Ing. Johann Hörtnagl - Werkzeuge GmbH

Products

HOODPECKER Austria stands for the best hand tools for landscape construction and forestry. Developed, tested and improved by people who work with them daily.

Perfect tools, adapted to the needs for daily use – Handmade in Austria.

About us

The history of our company dates back to 1907, when Johann Hörtnagl founded a forge and tool factory in Fulpmes in the Stubai Valley. This associated tradition and experience in the manufacture of tools allow us to be a reliable and powerful partner for industry, crafts and the do-it-yourself sector.

Our innovations, developed through our own prototype construction, CAD-supported design and state-of-the-art machinery ensure our customers a further development of products at a high technical level.

Our family business is thus constantly striving to anticipate the requirements of the future in order to offer our customers the best possible support.

We are constantly striving to be a reliable partner for you!

ENERGY-NEUTRAL tool production in Austria:

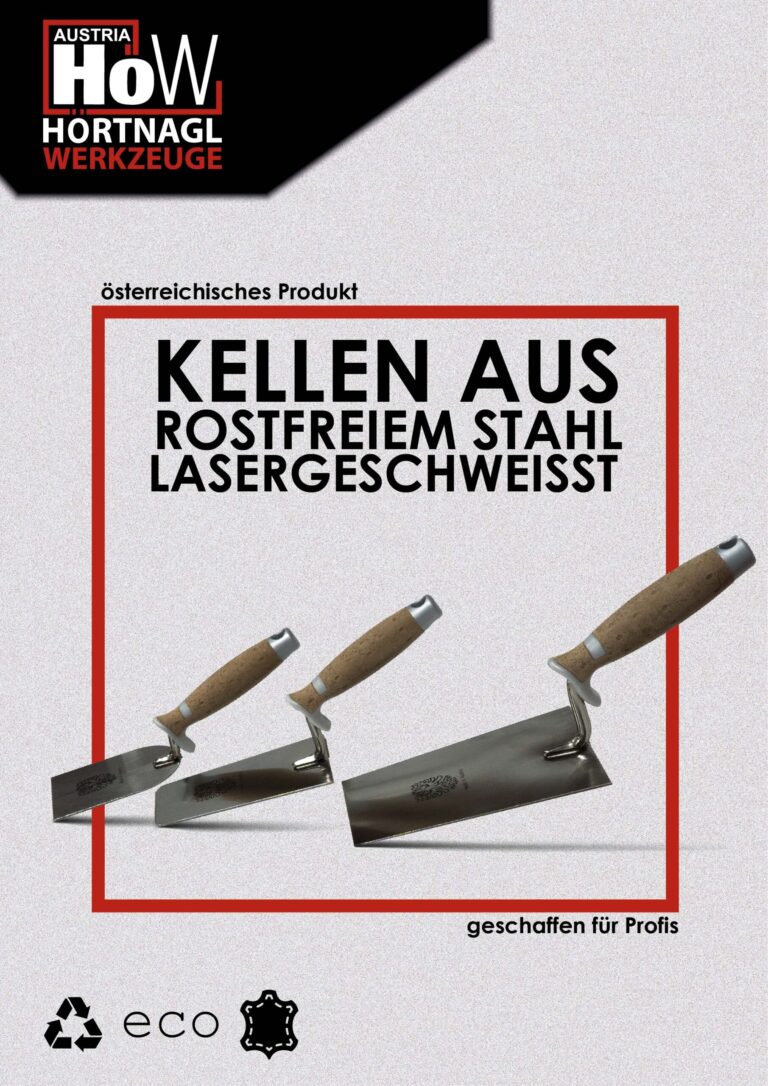

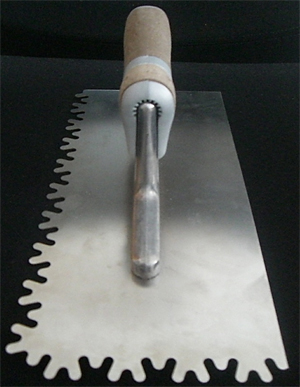

- Mason trowels

- Construction tools

- Roofer pliers

- Squares, measuring tools

- Garden and landscape construction

- Drywall construction

- Light metal tools

News

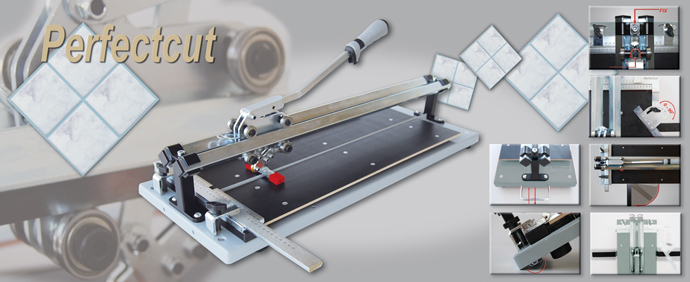

PERFECT CUT tile cutting machine

PERFECT CUT tile cutting machine New tile cutting machine...

more details

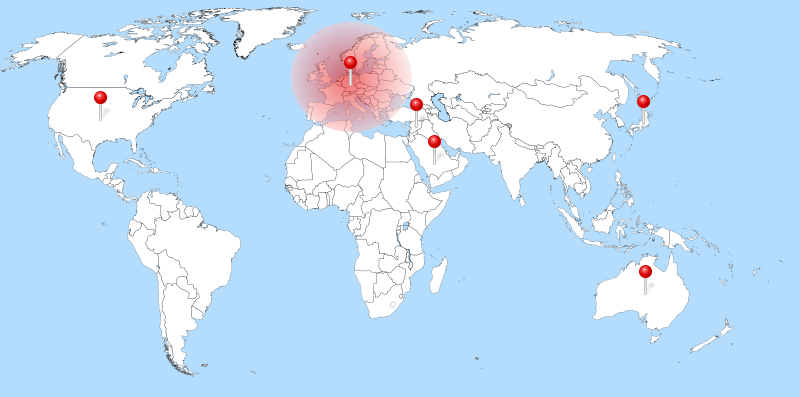

Distribution

We supply all structures of tool distribution, from corporations to hardware dealers, from department stores to online retail. This worldwide. We are very proud of this because we are one of the few companies that can respond to all particularities in the tool sector of different regions. For example, depending on customer requirements and region, we continuously produce 600 different shapes of mason trowels. We are also happy to put your requirements at the center of our production!

We would be happy to convince you of our products and service to win you as our distribution partner.

Contract Manufacturing

We also develop and manufacture special parts and components for various industrial sectors for our customers. From CAD design through prototype construction to finished parts, we can offer all phases of part development.

We can use the following technologies for your concern:

- punching

- bending

- extrusion pressing

- sawing

- cutting

- hot forming

- machining

- center machining

- grinding

- polishing

- resistance welding

- flash butt welding

- CNC milling and turning production

- Plastic injection molding

The following surface treatments can be offered: from polishing and tumbling to high-gloss polishing, as well as all common galvanic treatments.

Materials used: Steel, stainless steel, brass, aluminum alloys, plastics.